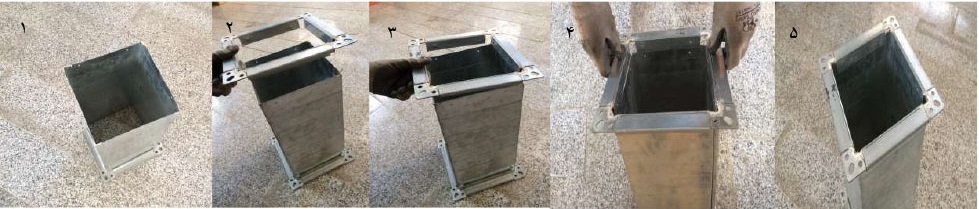

A piece called corner is used to connect the flanges to each other and make the flange coil. In the following, we will examine the corner production steps.

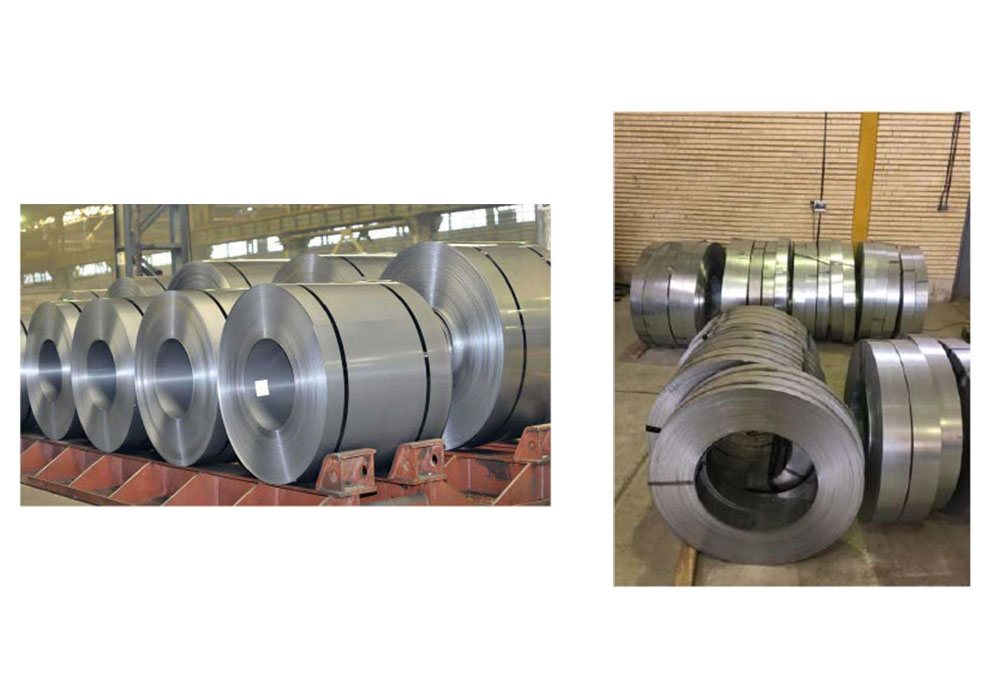

The first step in production is the supply of raw materials. The raw materials of the corners produced by Clintveneta are galvanized sheet with a thickness of 2 mm and oil sheet with a thickness of 3 mm.

The sheets used in widths of 1 and 1.25 meters are procured in rolls from reputable factories (Amir Kabir Kashan or Shahr Kurd) and are cut into rolls in smaller widths according to the size of the produced corners.

Rolls with a small width are fed into the entrance of the machine by the roll opener.

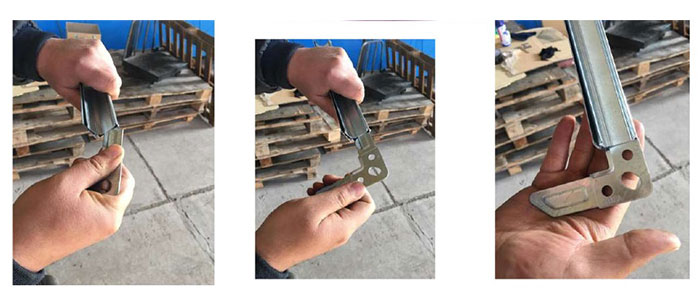

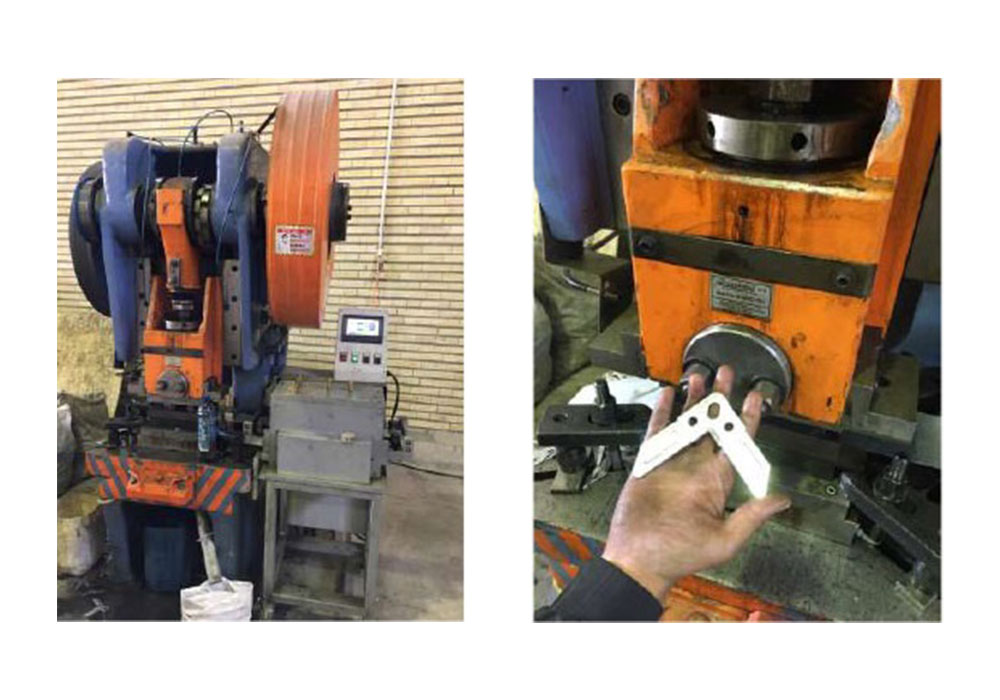

The sheet is transformed into the shape of the final piece by the pressing machine.

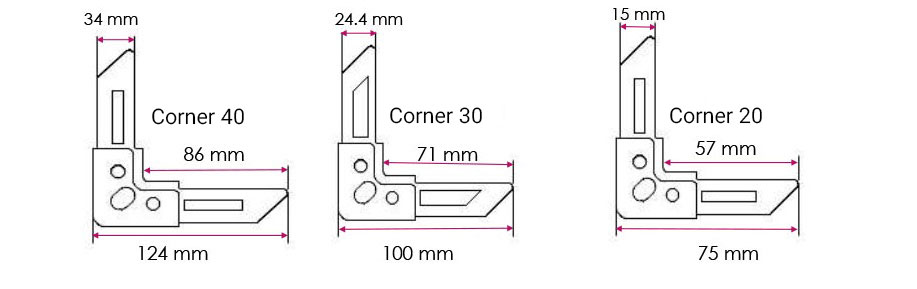

Clintveneta corners are produced in three sizes, 20, 30 and 40 mm, according to the manufactured flanges.

Corners of size 20 and 30 are produced from galvanized sheet with a thickness of 2 mm. Corner size 40 is produced from oiled sheet with a thickness of 3 mm and then plated.